Asia Tapco Industrial Co.,LTD

Imported industrial valves, compressor accessories, plate heat exchangers, maintenance

Release Time: 2021-11-01 22:16:15 Popularity: 1891

Working principle of disc valve

The disc valve is also called the rotating disc valve, which adopts a double-valve disc two-way sealing structure. Under the action of the cylinder torque, the valve shaft drives the valve core to make a plane rotation movement on the surface of the valve seat to achieve a quick opening and closing valve. It is designed specifically for materials with wear and erosion characteristics, and it can continue to work normally for a long time under severe working conditions.

The sealing surface of the disc valve core and valve seat is made of ceramic material or sprayed imported tungsten carbide alloy material. The hardness of the working state is more than 70HRC, has good wear resistance, and the service life is 3-5 times that of ordinary valves. The sealing surface of the valve disc is tightly attached to the valve seat by means of a spring. The spring pressure always keeps the valve disc tightly attached to the valve seat, and allows the valve disc to have displacement space in the vertical direction of the sealing surface, which makes the valve parts expand and contract by heat. And the deformation caused to compensate. The valve core and the valve seat are in a tightly integrated state under any circumstances, and it is difficult for the particulate medium to remain between the sealing surfaces when it is switched on and off. During the opening and closing process of the disc valve, the difference in friction between the valve seat sealing surface and the valve disc in the tangential direction causes the valve disc to rotate during an opening and closing cycle. Thereby, a self-grinding, polishing and cleaning effect is produced for the sealing surface, and the solid medium passing through the valve is shredded, so as to achieve the purpose of protecting the sealing surface and prolonging the service life of the valve.

Every time the valve is opened, because there is enough space in the valve cavity to make the disc push the medium away, the valve will not be blocked. In addition, every time the valve is opened to discharge materials, the valve body is eccentric to the flow channel, which generates vortex, and the formed material vortex will clean the inner cavity of the valve by itself. The valve channel has no obstruction to the fluid, and the pressure drop is small. The stuffing box adopts a spring-loaded mechanism, which greatly reduces possible leakage.

The disc valve opens and closes quickly (only rotates 90°), has good sealing performance, strong erosion resistance and abrasion resistance, good heat resistance, good use effect, and long life. It can be widely used in solid, gas-solid, solid-liquid transportation systems in coal chemical, silicon chemical, metallurgy, petrochemical and other industries.

Several structures of disc valves

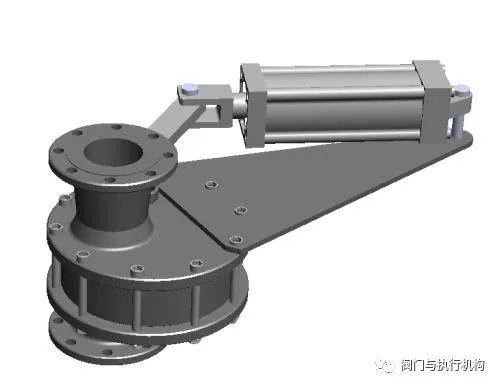

1. Angle stroke disc valve

2. Straight stroke disc valve

3.Three-way disc valve

Industry application of disc valve

Power Industry:

1. Coal ash discharge

2. Coal ash pipeline isolation

3. The bottom of the economizer is closed

4. Dry deslagging

Cement industry:

1. The pipeline of the cement pneumatic conveying system and the bottom of the silo are shut off

Chemical Industry:

1. Polycrystalline silicon powder production

2. Pulverized coal or coal slurry pipeline in coal gasification process