Asia Tapco Industrial Co.,LTD

Imported industrial valves, compressor accessories, plate heat exchangers, maintenance

Triple eccentric butterfly valve has high temperature and pressure resistance (up to 900), adopts multi-layer metal sealing structure, no mechanical abrasion, and can achieve zero leakage and low valve stem emission (below 100PPM).

In order to overcome the problem that triple eccentricity is tend to central stem stuck, Asia developed a patented labyrinth ring design to block polymers. It has a mutual sealing function and a fire protection design. It is suitable for the best device for adjusting the flow, cutting off or connecting the fluid in different media pipelines such as petroleum, chemical industry, metallurgy, electric power, and food.

Testing standard: API 598 and API 6D metal seated

Certification: WCB fire proof certification / ISO 15848

Triple eccentric butterfly valve has high temperature and pressure resistance (up to 900), adopts multi-layer metal sealing structure, no mechanical abrasion, and can achieve zero leakage and low valve stem emission (below 100PPM).

In order to overcome the problem that triple eccentricity is tend to central stem stuck, Asia developed a patented labyrinth ring design to block polymers. It has a mutual sealing function and a fire protection design. It is suitable for the best device for adjusting the flow, cutting off or connecting the fluid in different media pipelines such as petroleum, chemical industry, metallurgy, electric power, and food.

Testing standard: API 598 and API 6D metal seated

Certification: WCB fire proof certification / ISO 15848

Design and manufacture are in full compliance with API standards.

Effectively improve the frequent internal leakage of gate valves and stop valves on pipelines.

The geometric design eliminates the possibility of operation jams, ensuring that the opening/closing torque changes significantly within the service life.

| Applicable places | Applicable fluid |

| Petroleum, chemical industry, metallurgy, electric power, food and medicine, water supply/drainage, gas transportation... and other pipelines | According to the different materials of the butterfly valve, it can be used in water, sewage, seawater, air, steam, gas, combustible gas, corrosive media, oil, food... and other media. |

Product specialty and advantage

Zero abrasion

Metal sealing to make sure the best sealing ability

Hight pressure and temperture resistence

Leakage Level: API 6D

Aisa patented designed - labyrinth ring design to block the polymers leak into stem, prevent the stem happen to stuck

Triple butterfly valve can replace the big size gate valve due to funtion is in same efficiency with the cheaper price

Face to Face can be customized by any demand in any situation

1. The valve seat and valve body can reach API598, API6D zero leakage standards

2. Low VOC spill of valve shaft: Helium test leakage is less than 1×10-6 atm‧cc/s

3. No material aging and elastic failure problems

4. With excellent two-way sealing function

5. The valve seat is made of high hardness, wear resistance and corrosion resistance materials

6. The all-metal structure has fire safety features

7. Double Packing, Bearing Protector, Life Loading effectively reduce the problem of shaft spillage

8. In addition to the above features, Aixia's new replaceable triple eccentric butterfly valve greatly increases the convenience of maintenance

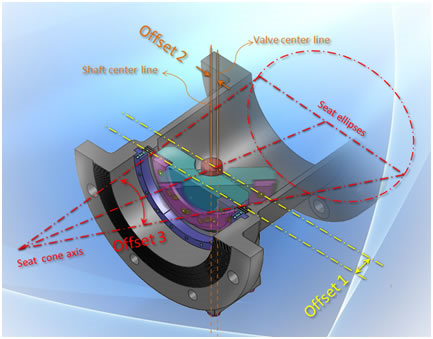

First eccentricity/Offset 1: The shaft deviates from the center line of the sealing surface

The second eccentricity/Offset 2: The axis deviates from the center line of the pipeline and the valve

Third eccentricity/Offset 3: The valve seat and the sealing ring are completely separated from each other during the opening and closing process with geometric shapes

The three eccentric combination uses the cam effect to eliminate the friction between the valve seat and the sealing ring, overcome the problem of wear and leakage, and optimize the contact characteristics of the valve seat and the sealing ring to ensure the service life of the valve.